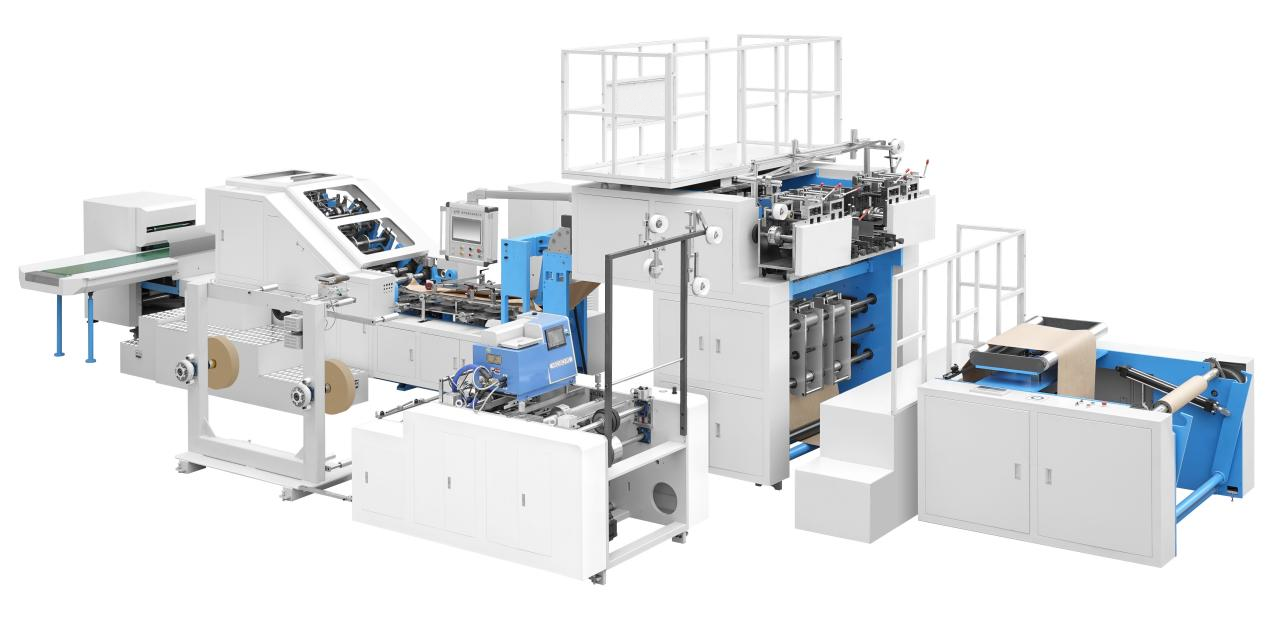

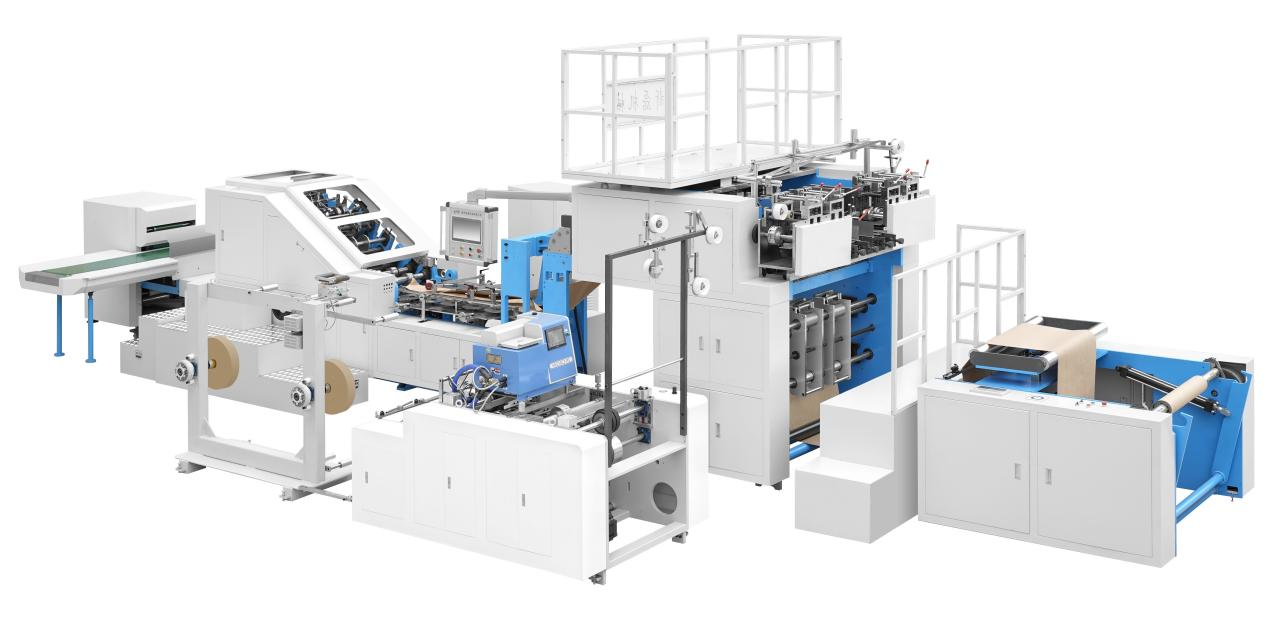

Automatic Round Rope Square Paper Bag Machine

Performance and use:

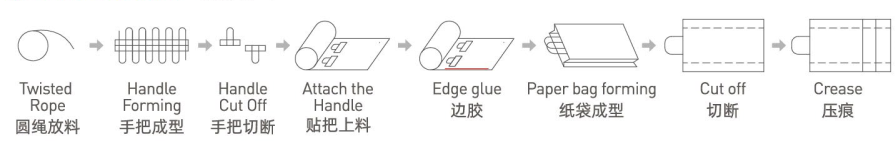

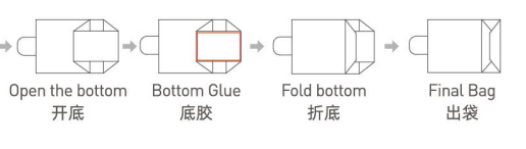

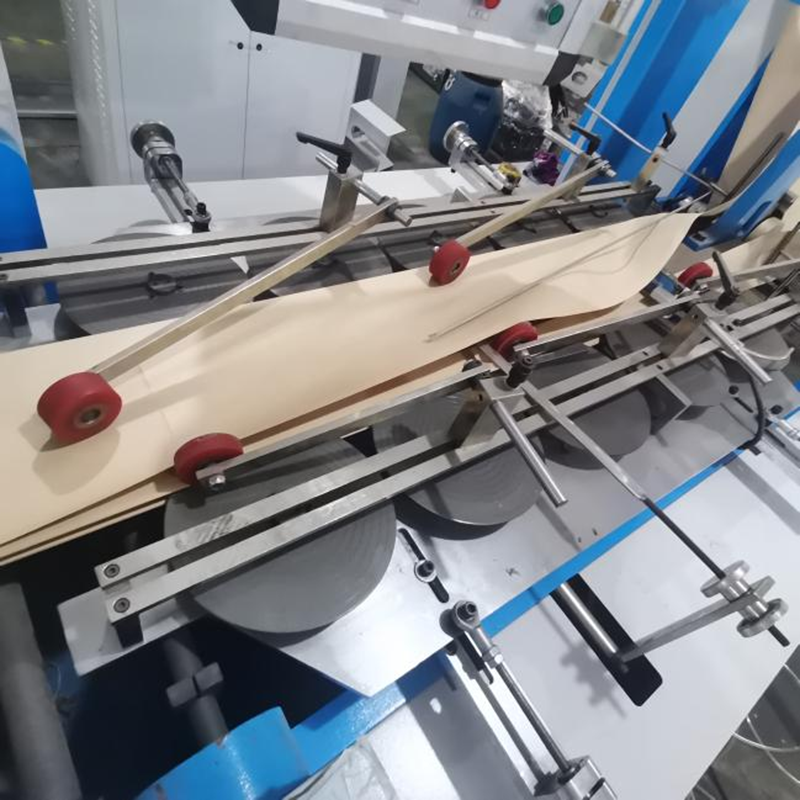

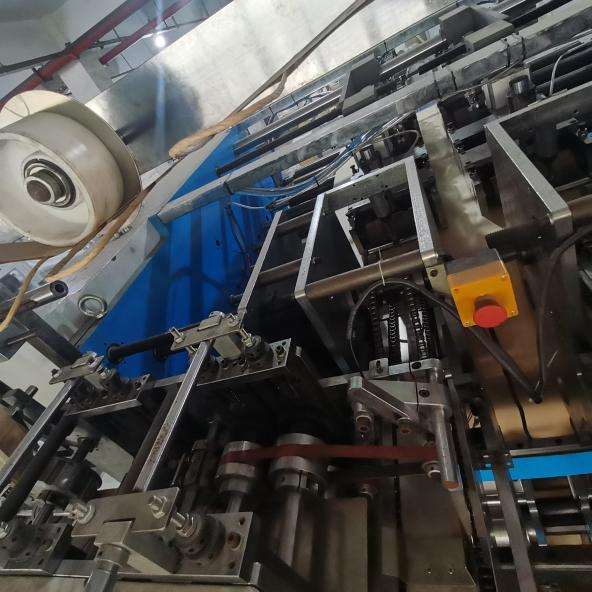

Fully automatic square bottom paper bag machine is used to produce hand-held paper bags with hand handles. This machine is especially suitable for the bulk production of shopping bags in food and clothing industries. The machine by hand holding machine will roll of rope and paper roll system arm in arm, arm in arm through the transmission system to put the unit will be primary or printed roll paper twine again a preliminary point break, patch glue, automatic paste hand wan, again by the host with a hand holding the paper to the edge glue, into the bottom of the cone, cutting, creasing, glue, bag forming and piped out of the bag, The whole process is done simultaneously at once. This machine adopts Japanese mitsubishi imported high speed motion controller (CPU), through the high speed bus control servo operation, to ensure stable movement, smooth motion curve, is the majority of printing and packaging manufacturers preferred automatic portable square bottom paper bag equipment.

Main feature:

1.Using Willon touch screen man-machine interface, the operation function is clear at a glance, easy to control

2.Adopt the Japanese original Mitsubishi motion controller, through the integration with the optical fiber, operation stability

3.Japanese Mitsubishi servo motor with German Schick color standard eye correction, accurate tracking printing bag size

4.The raw material loading and unloading adopts hydraulic dynamic lifting structure, and the unwinding adopts automatic constant tension control.

5.The raw material correction adopts brushless servo motor to reduce the adjustment time of paper roll alignment.

|

|

|

|

|

Model |

WT-ZD220T |

WT-ZD350T |

XL-ZD450T |

|

Cutting Length(total) |

230-370mm |

270-530mm |

270-530mm |

|

Cutting Length(total) |

230-330mm |

270-430mm |

270-430mm |

|

Paper Bag Width(total) |

140-220mm |

120-350mm |

220-450mm |

|

Bottom Width |

60-140mm |

60-150mm |

240-450mm |

|

Material Width(total) |

410-770mm |

380-1050mm |

|

|

Paper gsm(total) |

50-140g/㎡ |

60-150g/㎡ |

80-150g/㎡ |

|

Paper gsm |

50-130g/㎡ |

80-150g/㎡ |

80-150g/㎡ |

|

Paper Material Diameter |

1300mm |

1300mm |

1200mm |

|

Paper Core Inner Diameter |

76mm |

76mm |

76mm |

|

Handle Patch Length |

152mm |

152mm |

190mm |

|

Handle Patch Width |

50mm |

50mm |

50mm |

|

Paper Rope Spacing |

75mm |

75mm |

95mm |

|

Paper Handle Rope Diameter |

3-5mm |

3-5mm |

3-5mm |

|

Handle Patch Paper Roll Width |

100mm |

100mm |

100mm |

|

Handle Paper Roll Diameter |

1200mm |

1200mm |

1200mm |

|

Handle Patch Paper Weight |

100-135g/㎡ |

100-135g/㎡ |

100-135g/㎡ |

|

Mechanical Speed |

30-200pcs/min |

30-200pcs/min |

30-180pcs/min |

|

Paper Bag Production Speed |

30-18pcs/min |

30-180pcs/min |

30-150pcsmin |

|

Handle Speed |

30-150pcs/min |

30-150pcs/min |

30-130pcs/min |

|

Cutter Method |

Pinking |

Pinking |

Pinking |

|

otal Power |

380V/ 3Phase 4Line 28kw |

380V/ 3Phase 4Line 41.5kw |

380V/ 3Phase 4Line 41.5kw |

|

The whole machine pressure |

0.6-0.7MPa |

0.5-0.8MPa |

0.6-0.7MPa |

|

Total Weight |

15000Kg |

15000Kg |

15500Kg |

|

Machine Overall Dimension |

11000*4400*1800mm |

14000*6000*2400mm |

14000*6200*2400mm |

|

|

|

|

|

|

|

|

|

|