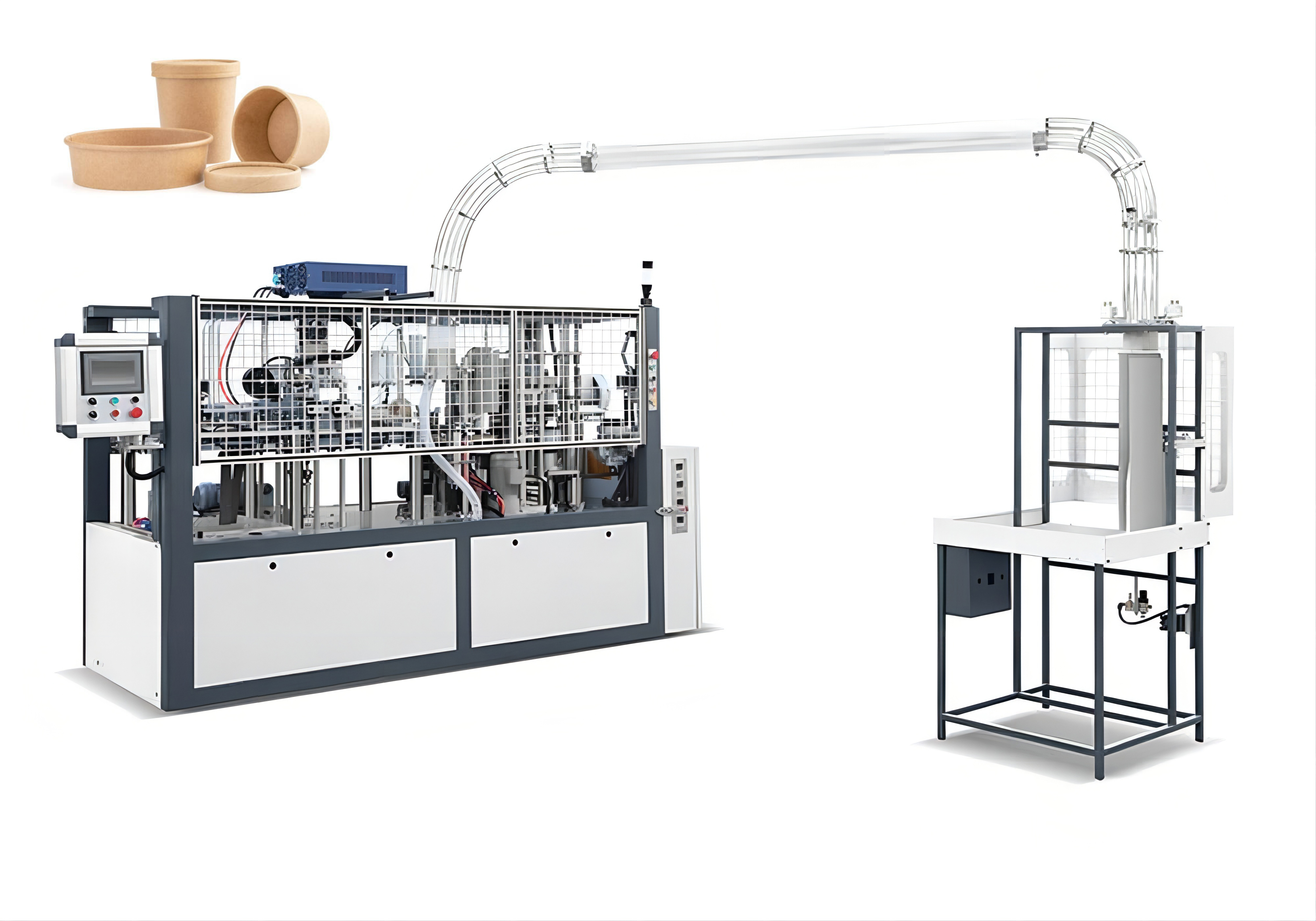

RW-150 Paper Bowl Forming Machine

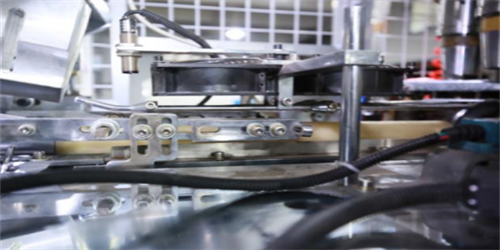

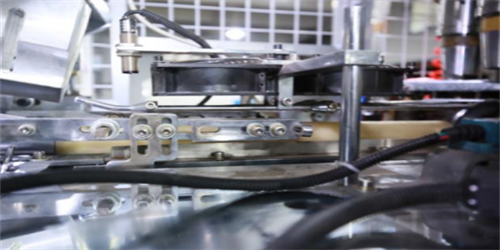

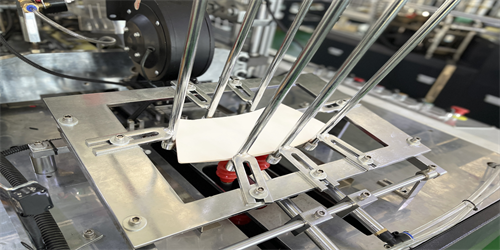

The frame of the WT-150 full-automatic double-sided PE coated paper bowl forming machine is an inclined frame, and the cup drop rate reaches 99.9%. It is developed on the basis of fully absorbing the latest Korean paper bowl machine according to the domestic situation, through automatic paper feeding (printed fan-shaped paper), two preheating, sealing (bowl wall), oil injection (lubricating and rolling (Mouth), bottom punching (automatically punching the bottom of the bowl from the roll paper), two-stage bottom heating, knurling (bowl bottom sealing), curling (rolling top), rolling water line, unloading bowl collection and other continuous processes , And has the functions of photoelectric detection, fault alarm, counting, etc. It is an ideal equipment for producing large-capacity and large-caliber bowl-shaped containers such as paper soup bowls, instant noodle bowls, and take-out paper bowls.

WT-150 paper bowl machine is mainly used to produce "single and double PE coated" paper bowls. This machine is easy to operate (one person), stable performance, small area, high efficiency, it is the first choice for investment and entrepreneurship

|

Model |

WT-150 |

|

Paper Cup Size |

20-32oz (550-1000ml) |

|

Cup diameter (MM) |

90-150 |

|

Cup bottom diameter (MM) |

70-125 |

|

Cup height (MM) |

50-105 |

|

Rated Speed |

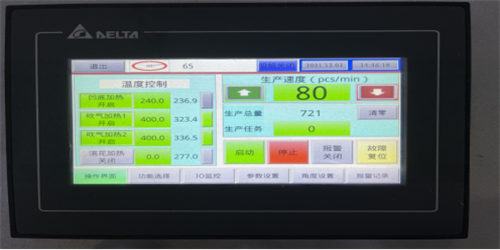

60-80 PCS/minute (depend on cup size, speed different)Speed affected by cup size, paper quality & thickness |

|

Raw Material |

One-side or two-side PE coated paper(Singe PE or Double PE coated paper) |

|

Suitable paper weight (g/m²) |

170-380 |

|

Power Source |

380v-50/60hz 3-phase |

|

Total Power (KW) |

16 |

|

Working Power (KW) |

10 |

|

Total Weight (KG) |

2500 |

|

Pack Size (L*W*H)(MM) |

2800*1350*1800 |

|

Working Air Source |

Air pressure 0.6-0.8Mpa |

|

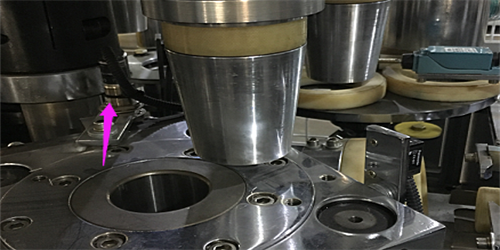

Cup Side Welding |

Ultrasonic |

|

Cup Bottom Knurling: |

HOT WIND system |

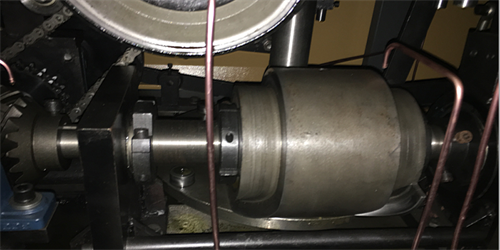

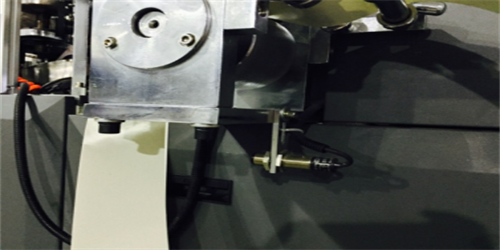

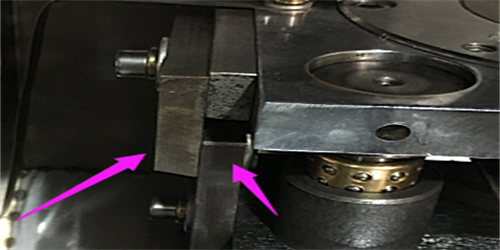

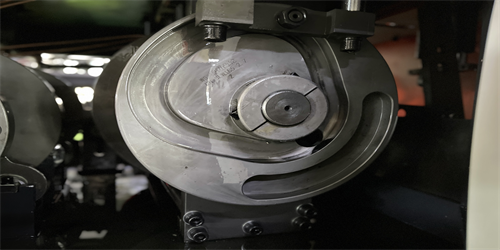

| Open cam instead of index gear box to divide the steps, Compare with index gear box: Open cam Advantage: Can be see by sight, Easy maintenance, Easy oil, Easy replace bearing if have problem. Shortage: opened, if drop objects or tools maybe damage the cam and bearing. Oil and clean is important. |

|

||||

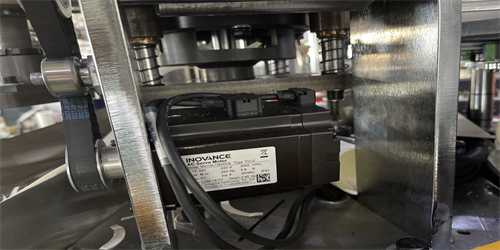

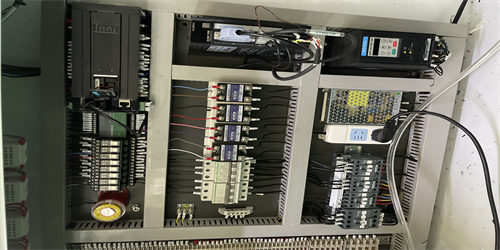

| PLC and program control the machine, Intelligent program controls all steps, Easy operate, Fault auto stop and indicate, With advanced Encoder drive, keep machine more efficient, reliable. |

|

||||

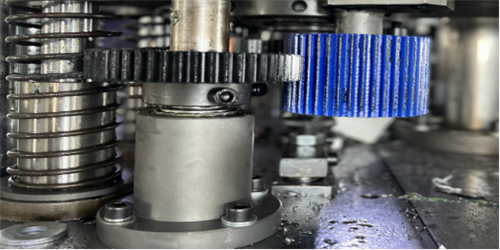

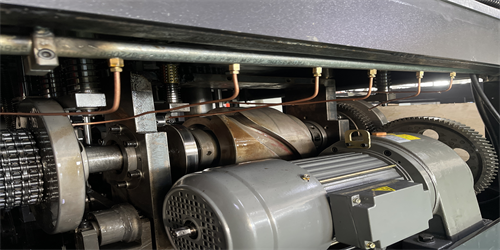

| Quality Gears and axis keep the machine stable and reliable |  |

||||

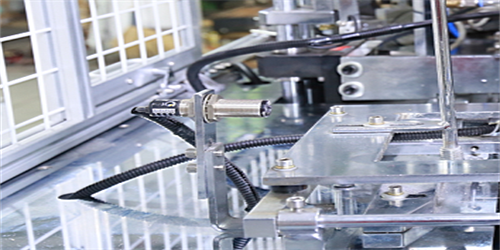

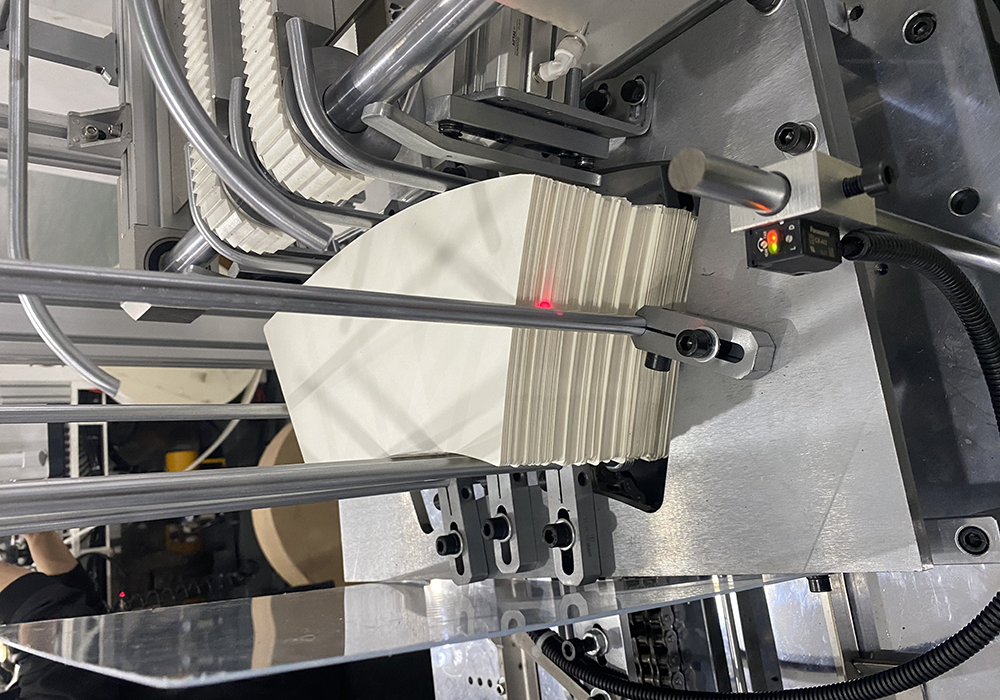

| Sensor 1: Cup fan shot sensor (fan short alarm). |  |

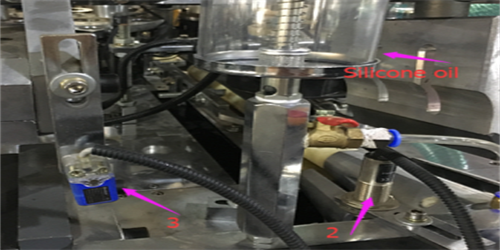

Sensor 2:Cup fan come detect sensor Send signal to ultrasonic, prepare work. |

|

||

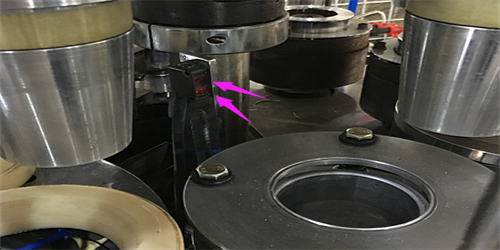

| Sensor 3: Ultrasonic work sensor, Cup fan pass, sensor 2 work, sensor 3 approach Then ultrasonic work. |

|

Sensor 4:Cup body sealing sensor No sealing, alarm and stop. |

|

||

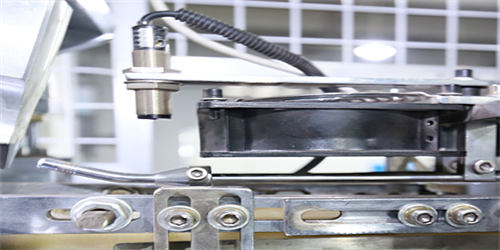

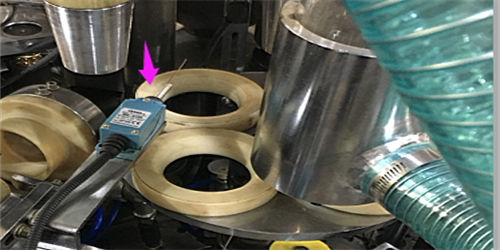

| Sensor 5:Cup body transfer sensor Only detect cup body on mold, bottom feed and punch. |

|

Sensor 6:bottom disc punch sensor, No bottom, Sop Sensor 5 work, Bottom feed and disc punched. |

|

||

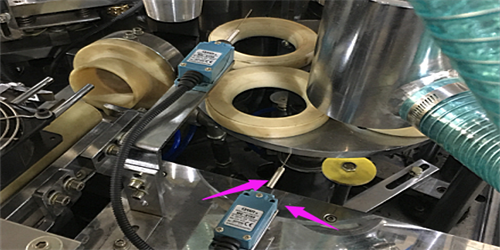

| Sensor 7: Cup bottom pull sensor, Bottom reel feed short, auto pull. |

|

Sensor 8: Cup drop sensor Cup drop in knurling, curling furnace, stop. |

|

||

| Sensor 9: Cup pass sensor If cup do not discharge from mold, pass over, stop. |

|

Sensor 10:Cup Blow Out Sensor No discharge, pass bay, Stop. |

|

||

| Sensor 11: Machine position sensor Control the motor stop position. |

|

Sensor 12:count sensor, Counter sensor on collector/stacker, (if no need collector, no counter sensor). |

|

||

| Parts of the machine | |||||

| Blower to cool the Ultrasonic System |  |

Fan cool the cup body (after ultrasonic sealing) |  |

||

| Air gun, Blow the paper edge, rust, Help to clean the machine |

|

Bottom edge cut knife, Cut bottom edge to pieces |

|

||

| Main motor |  |

Cup bottom paper sheet feeding motor |  |

||

| Long distance paper feeding, guide the paper to right position |  |

Bottom directly feed to cup cone, Easy control and more precession |

|

||

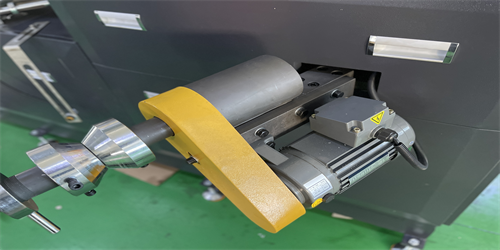

| Knurled motor |  |

Slotted wheels-make the machine drive |  |

||

| Machine lubrication oil supply system |  |

Ultrasonic welding device |  |

||

| Electrical control box (all international brand electrical appliances) |  |

Collecting cup machine (with counting function) |  |

||

|

|

|

|

You need to buy bowl fan

|

|

|

|

Reference drawing of paper cup specifications that can be produced by this machine

|

|

|

|