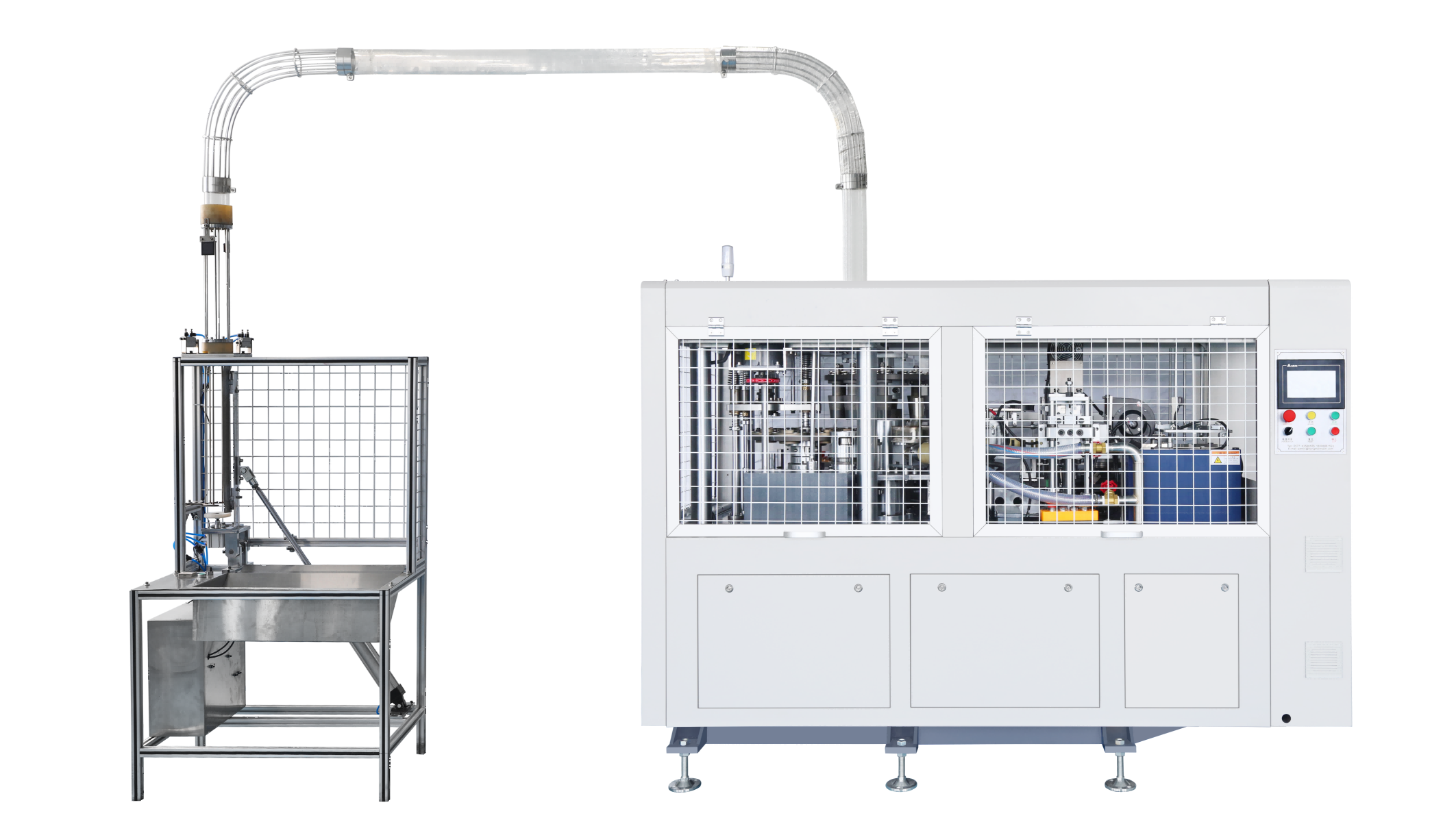

RW-115S Fully Automatic Paper Cup Forming Machine

Introduction:

HM-115S Fully Automatic Paper Cup Forming Machine has advantage of high performance high efficiency and high-quality; The overall steel plate body and the oil-spaying lubrication system ensure the long-term normal and stable operation of the equipment.

Energy efficient:

The advanced high-precision cam drive and gear drive make the forming of each station accurate; the servo tracking bottom feeding paper locks the size of the cup bottom paper, effectively saving raw materials.

Humanize:

The human-machine interface PLC system controls the stable operation of the whole machine for a long time; the automatic counting and reasonable setting of the cup collection table can replace the busy work of manual work.

Scope of application:

Used for producing single and double sided PE coated paper cup, for hot & cold drink, and other food paper containers.

|

Model |

HM-115S |

|

Paper cup specifications |

3-12Ounce (according to cup size change the mould) |

|

Raw material |

Single side pe or double sides PE coated paper |

|

Speed |

100-120pcs/min |

|

Suitable paper weight |

160-300g/㎡ ±20/㎡ |

|

Voltage supply |

380V (220V) 50Hz |

|

Cup’s range |

Top:45-90mm Height:35-115mm |

|

Working air source |

0.4-0.6Mpa 0.4m³/min |

|

Total power |

11KW |

|

Weight |

2800KGS |

|

Measurement(L×W×H) |

Machine:2300mm×1200mm×1800mm |

|

Cup storage rack: |

|

|

Cup wall sealing |

Evergreen ultrasonic |

|

Bottom knurling |

Blowing heating system |

|

Can customize molds according to customer requirements |

|

Main Configuration:

|

Item |

Main Parts |

Origin |

|

1. |

Touch Screen |

TAIWAN Delta |

|

2. |

Temperature Mold |

KOREA AUTONICS |

|

3. |

PLC |

TAIWAN Delta |

|

4. |

Embossing Motor |

SHANGHAI |

|

5. |

Bottom Feeding Motor |

HANGZHOU |

|

6. |

Power Supply |

CHINT |

|

7. |

Driving Scored Pulley |

SHANGDONG |

|

8. |

Ultrasonic |

ZHEJIANG |

|

9. |

Pneumatic Element |

ZHEJIANG |