RW-160 Full Servo Paper Cup Machine

The full servo model is designed and manufactured based on the traditional model (chain gear transmission structure). It not only inherits the stable operation of the traditional model but also improves the advantages of speed, accuracy, and quality, all thanks to the 13 full servo motors in the whole machine. They each perform their duties to control actions such as absorbing paper, turning cups, and topping cups. They are easy to operate, and can quickly identify and solve faults.

|

|

Technical Parameters:

|

model |

Full Servo Paper Cup Machine |

|

paper cup specification |

4-16oz |

|

Gram weight |

170-350g |

|

Material |

PE/Double PE/PLA coated paper |

|

Speed |

130-160pcs/min |

|

power supply |

3 phase 380V |

|

total power |

33KW, 13KW/h |

|

Gas source |

0.6Mpa, 0.5m³/min |

|

Machine Measurement |

3000x1600x2200mm |

|

Weight |

3.5T |

|

|

|

|

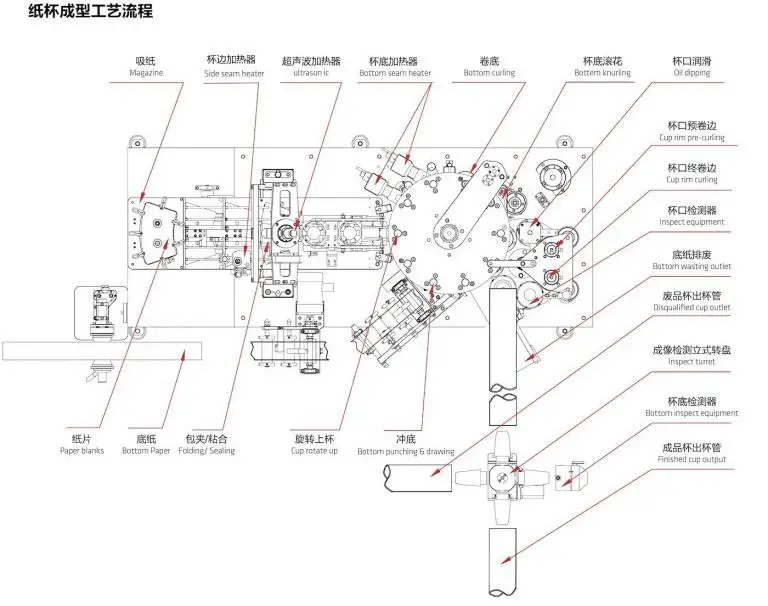

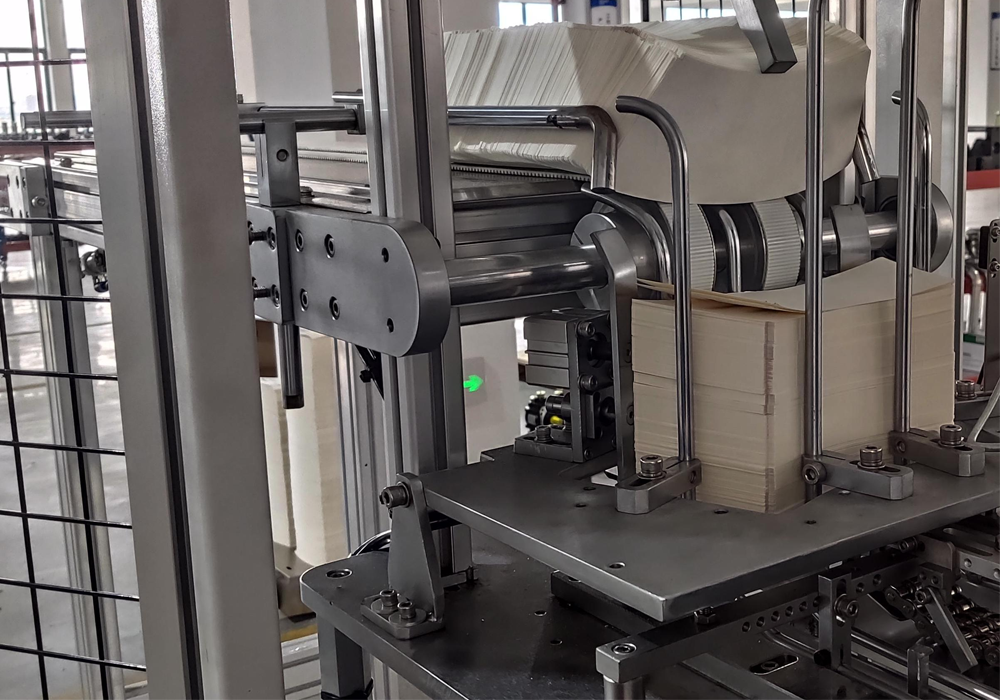

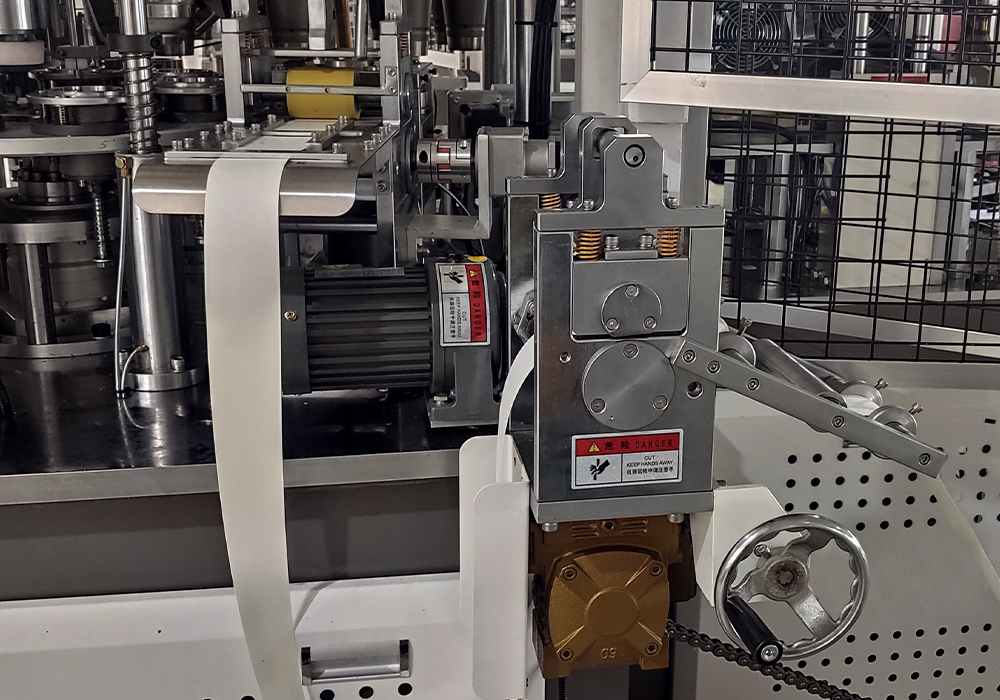

| 1.The paper falls to the designated position through the conveyor belt, and then the servo motor below controls the suction cup to grab the paper and place it on the chain for transportation | 2.Preheating the side of the paper chooses Weihe |

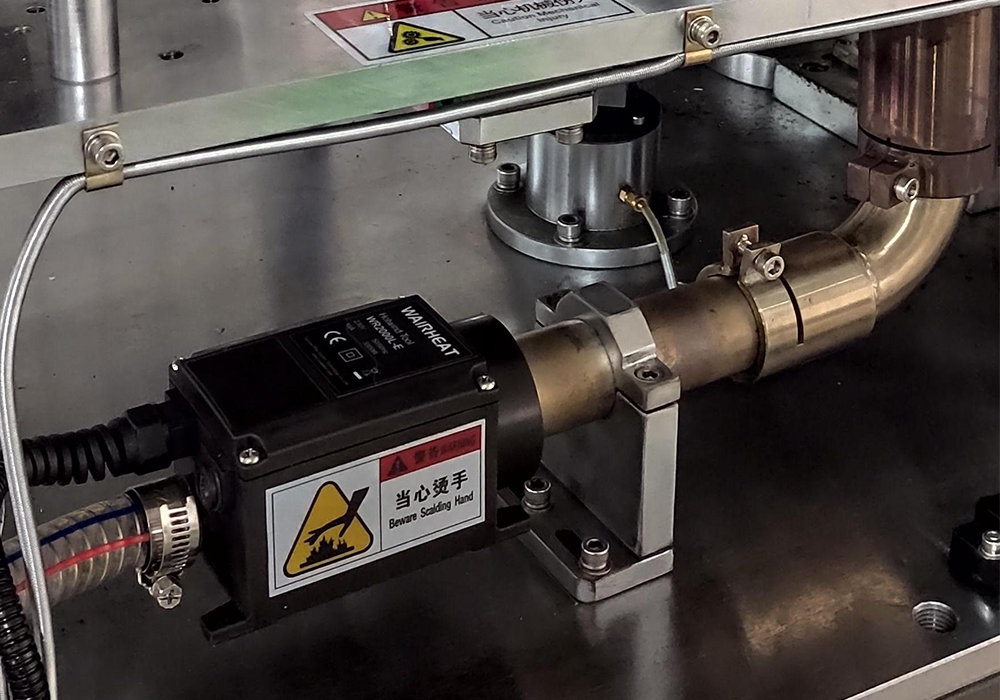

3.Preheating the side of the paper chooses Weihe |

4.Efficient ultrasonic bonding technology on the sides |

|

|

|

|

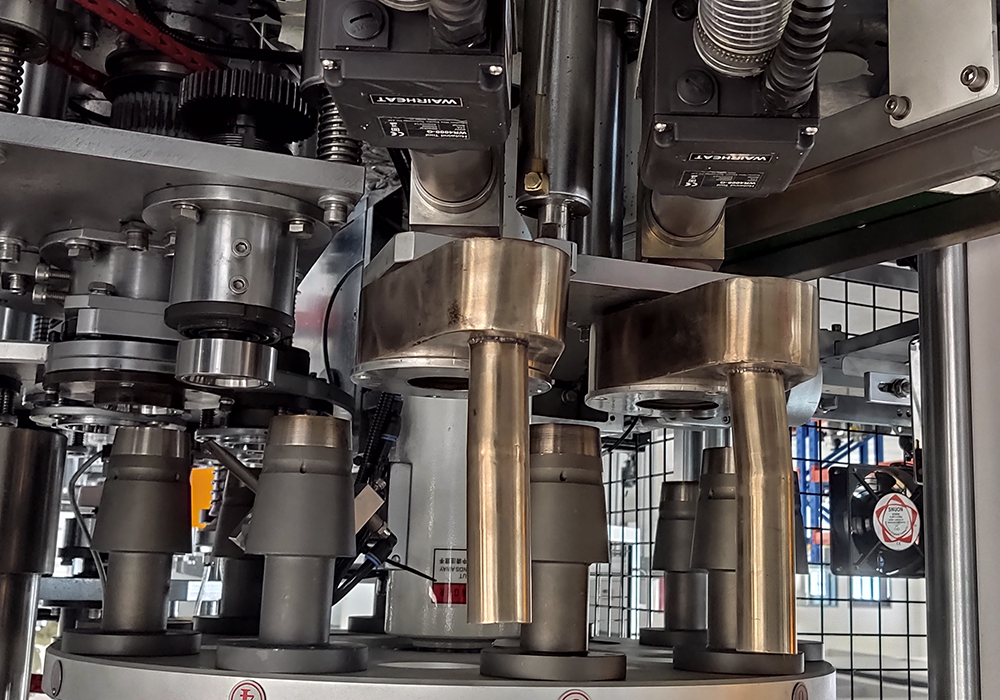

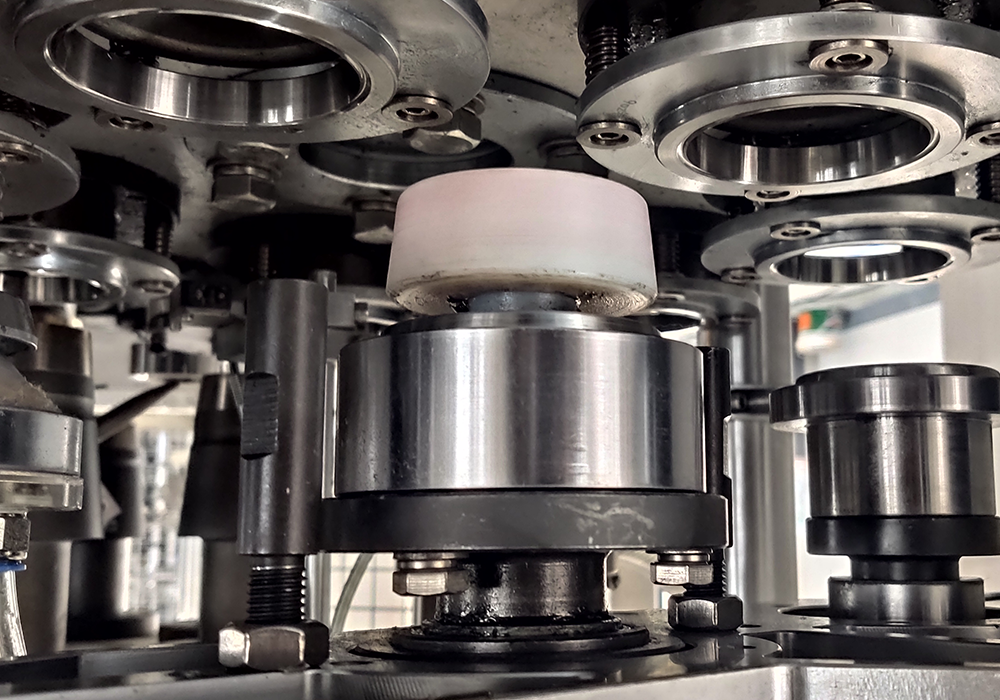

| 5.Cup bottom molding adopts double-station heating and double-station knurling process, which meets and meets the double requirements of customers for beauty and firmness |

6. Efficient and beautiful double-station process is adopted for the crimping of the cup mouth |

7.Rapid stamping bottom paper mold |

8.Cost-effective liner feeder |